Erro de formato de e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Notícias

Aqui, você pode descrever uma peça de texto que deseja expressar.

V.S. pneumático Elétrico, conheça sua diferença

Peças de mão dental, como peças de mão contra ângulo e peças de mão turbo, hoje são vistas como mais do que apenas "mercadorias". No entanto, como ficará claro para você abaixo, essa visualização não é suficiente. A peça de mão dentária é a ferramenta mais importante do dentista e uma parte essencial da prática odontológica moderna.

V.S. pneumático Elétrico

Existem dois sistemas para dirigir o BUR: o sistema pneumático e o sistema elétrico. Nos sistemas pneumáticos, turbinas e motores aéreos são projetados de maneira diferente.

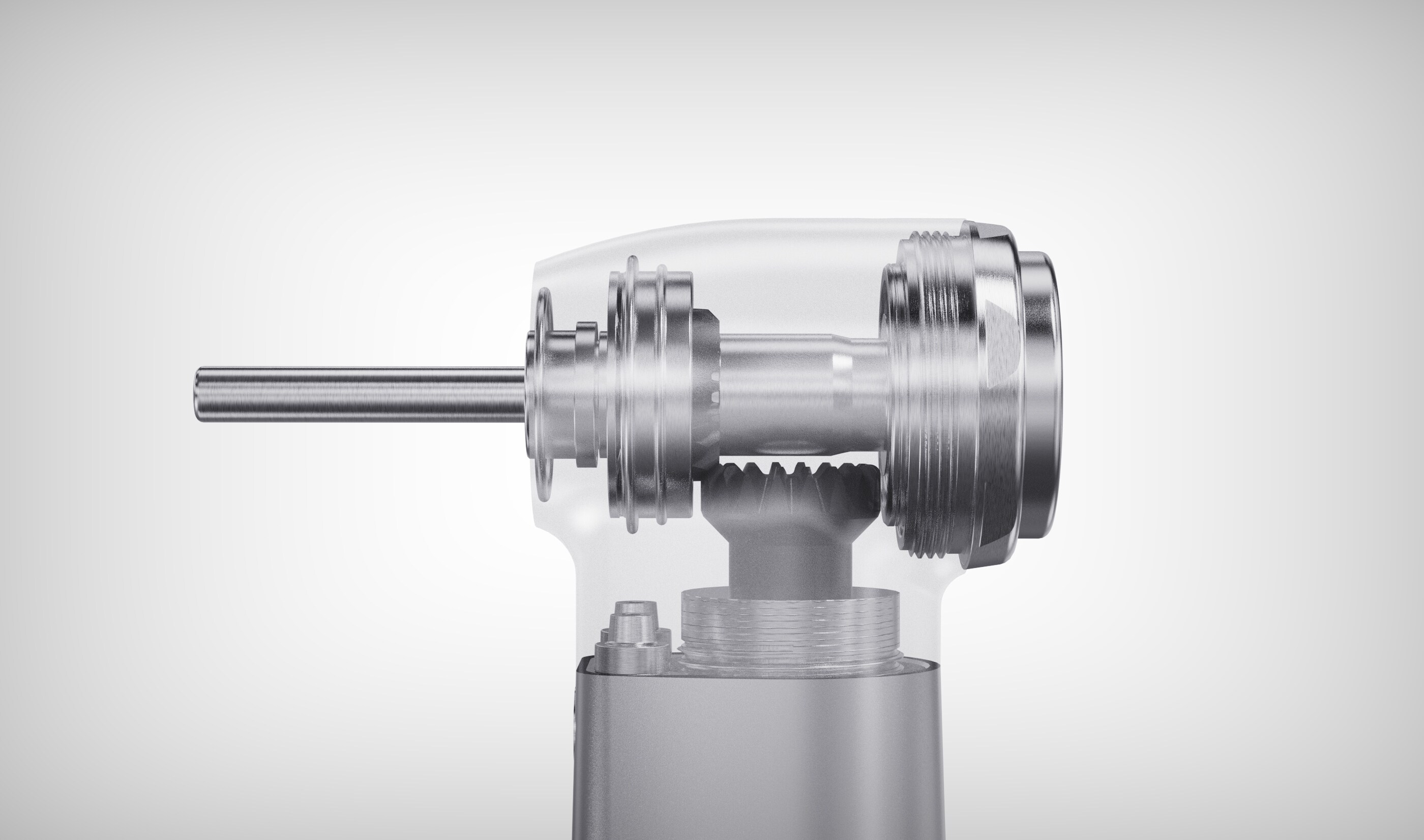

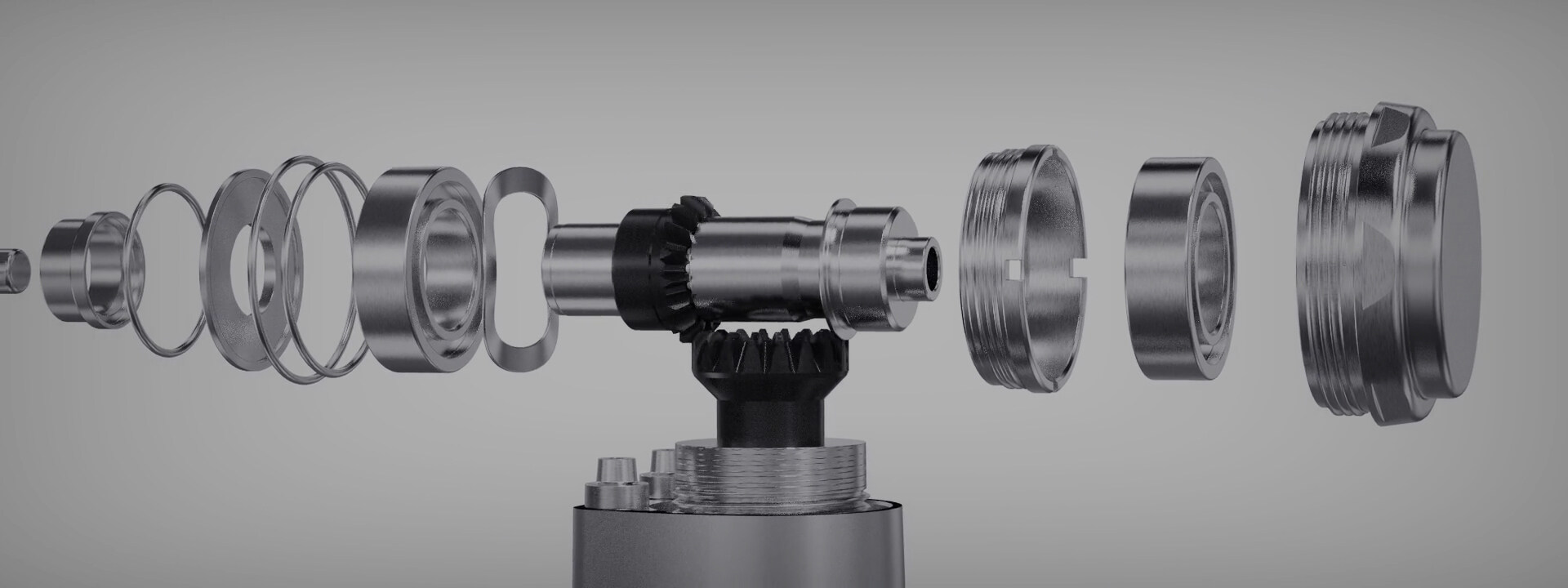

Para a turbina, o rotor dirige o BUR diretamente. O impulsor do rotor é acionado por gás comprimido. A velocidade inativa da turbina pode ser de até 400.000 rpm. A velocidade real de trabalho depende da força aplicada e é cerca da metade da velocidade ociosa, que é de cerca de 150.000 a 250.000 rpm. A potência máxima alcançável em sua faixa de rotações é de 10-26 watts.

Por outro lado, o motor de ar conduz a broca indiretamente através de uma peça de mão curva ou de uma peça de mão reta. A velocidade máxima que o motor de ar pode atingir é de 25.000 rpm. Existem contra-ângulo com diferentes taxas de aceleração e velocidade. Portanto, uma peça de mão contra ângulo contra um motor de ar com uma taxa de redução de 2: 1 pode atingir uma velocidade de rotação de cerca de 12.500 rpm.

O motor elétrico tem uma velocidade ociosa de até 40.000 rpm. Para uma peça de mão contra o ângulo de aceleração de 1: 5, o BUR correspondente gira a 200.000 rpm. A potência máxima é superior a 60 watts e o torque é de cerca de 3ncm. Isso significa que o ângulo de contra-ângulo elétrico não diminui ou para quando a broca corta diferentes tecidos dentários ou materiais ortopédicos.

O telefone mantém uma RPM quase constante, com ou sem carga. O BUR da peça de mão contra-ângulo corre mais estável do que a peça de mão turbo. As brocas de mão em ângulo têm menos vibração do que as bolsas de mão turbo. O aumento da estabilidade significa que os preparativos funcionam com maior precisão, em velocidades mais rápidas e com menos calor no tecido dentário.

O desenvolvimento contínuo

A tendência para motores elétricos começou na Europa. Um motivo importante é o custo da instalação de novas linhas pneumáticas nos edifícios existentes. Há também uma razão óbvia de que as unidades elétricas não são apenas mais simples de instalar, mas também mais eficientes de usar.

Décadas depois, os motores elétricos são muito populares na Europa e na Ásia. As inovações tecnológicas em design, materiais, torque e iluminação também estão tornando os motores elétricos cada vez mais populares na América do Norte hoje. Os motores elétricos tornam o trabalho das clínicas odontológicas mais fáceis e rápidas.

Resumindo

Somos um fabricante profissional, mais perguntas, não hesite em entrar em contato conosco.